News Releases

April 25, 2024

Enhance Your Operations: Leveraging Magnetic Separators for Efficient Material Handling

Are you using a magnetic separator with your equipment, or do you plan to? Would this kind of vibration equipment improve your operation?

SUMMARY:

🔥 smooth conveying of powder ash at nearly 4 tons / hour

🔥 efficient removal of iron using a magnetic separator

🔥 linear motion created by two 6 pole Uras Vibrators

🔥🔥🔥 The low-maintenance, high-reliability that comes with Uras equipment

A client came to us requiring incinerated ash be conveyed, but they needed an efficient way to remove contaminants. In this case, approximately 10% of the material were tiny bits of iron, some nearly the same size as the ash. They required a way to remove this iron before transportation to the next process.

We suggested using a conventional conveyor, with the addition of a magnetic separator used to remove the iron flakes. In order to do this, our engineers created a stainless steel opening through the mid section of the conveyor, allowing access to powerful magnets. This would remove the iron, while leaving the stainless steel section, a non-magnetic material, unaffected.

April 19, 2024

Innovative Solution for Nickel Briquette Transport in EV Battery Production

Our client needed a quick and efficient way to transport nickel briquettes that were halfway through the production process from one application to the next. These briquettes would later be used in EV batteries. They of course had a lot of options in front of them for something like this, but the best and most reliable ended up being a vibrating feeder. The two vibrating motors on top provided the smooth linear motion, while the enclosed trough optimized safety concerns for their workers.

🚗 Enclosed design to maximize safety, easy to open ports and see through carbonite window to maximize convenience

🚗 Able to safely feed materials at extremely high temperatures

🚗 Powered by two 6 pole Uras Vibrators, top in the industry in reliability and design

April 11, 2024

Recycling RPF: Uras Vibrators in Action

Are you working in a recycling facility? Have you made the move to vibration?

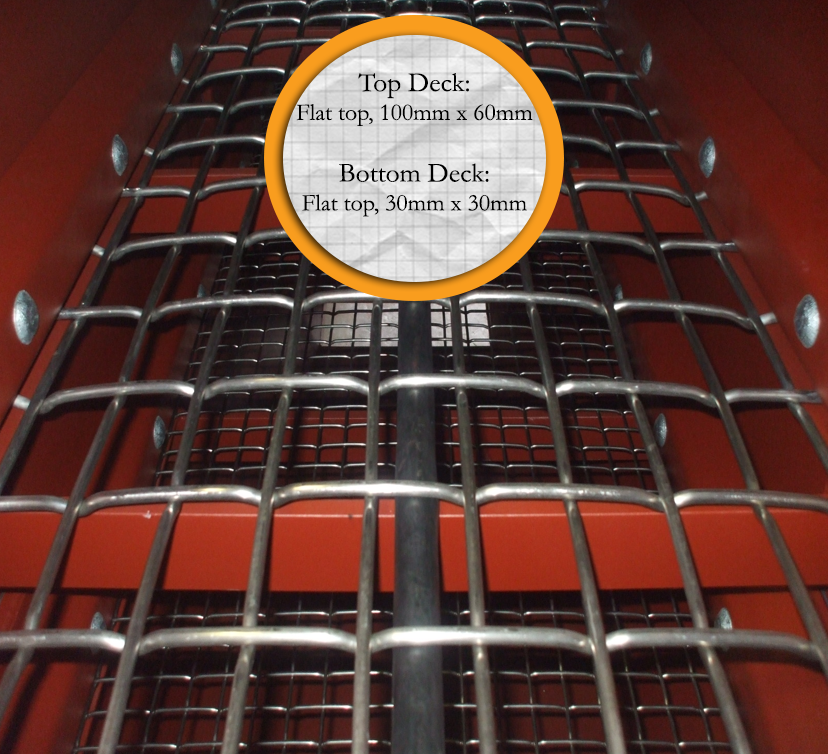

Industrial vibration equipment is used to improve the efficiency of recycling facilities across the world. Uras Vibrators are extremely helpful to the recycling industry, and such is the case in this screen that aids in the production of RPF (refuse paper & plastic fuel). Our client needed a double deck machine with three levels of screening, that separates bits of waste plastics that would eventually go into the creation of RPF, a solid fuel that is extremely environmentally friendly.

The screen is powered by two extremely efficient 8-pole vibrators, and comes with multiple easy-open viewing ports as well as an easy-access deck drawer for either sanitation/maintenance or switching out the decks in case a different level of separation is needed.

April 4, 2024

Recycling and Water Reclamation with Innovative Engineering

Some of our machines are used for recycling. Others are used as part of the smelting process. This guy is used for recycling bits and pieces of the smelting process! The waste water used for cooling was first put through this screen as part of a filtration process to remove solids before it was converted to usable water. This allowed the material to be recycled and the water to be reclaimed.

♻ 13mm screen used to smoothly separate material

♻ assisted in water reclamation as well as material recycling

♻ powered by two 6 pole Uras Vibrators, linear motion has never looked so reliable, or so blue!