News Releases

March 28, 2024

Keeping the Heat On: Solutions for Hot Material Transport

March 21, 2024

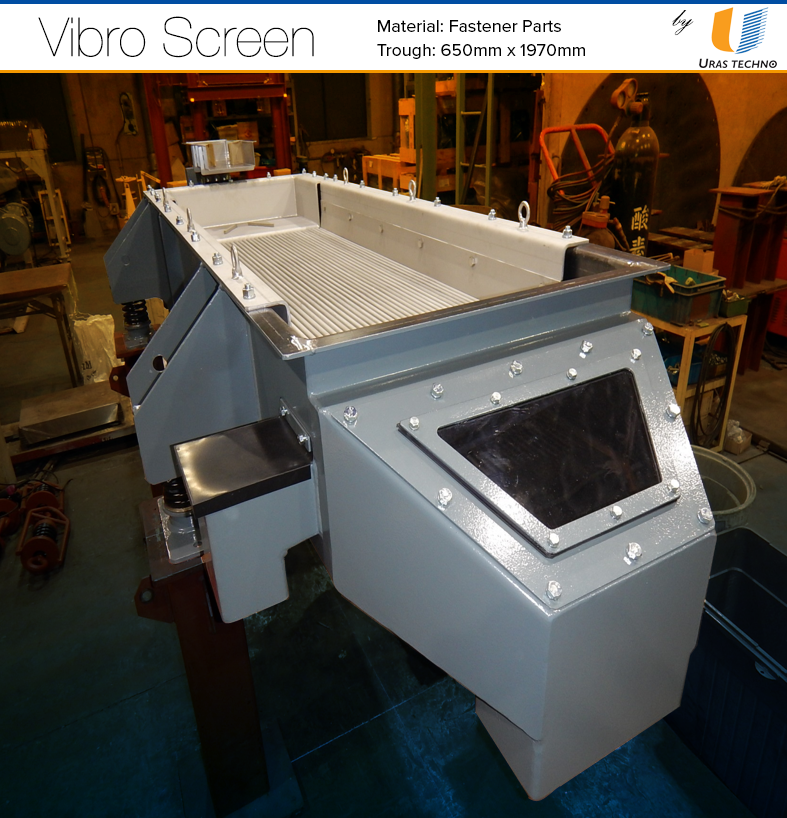

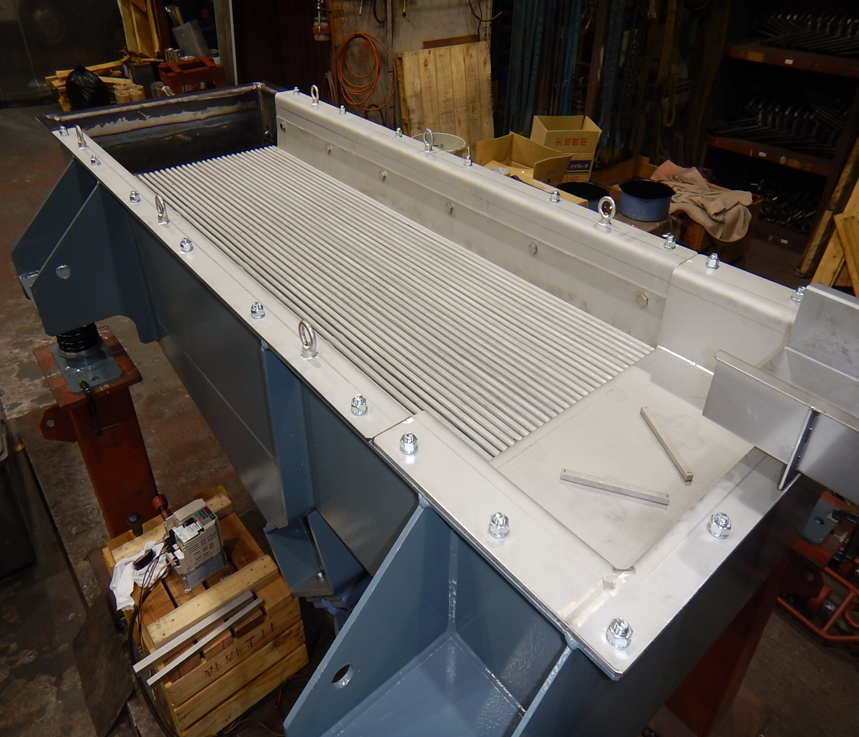

Precision Sorting with Uras Techno’s Vibro Screen

This Vibro Screen was used to sort fastener parts fed from a magnetic feeder into 2 sizes. The machine includes an inspection window made from a strong polycarbonate, and a mesh with 5mm slits for screening.

Wanna know what Uras Techno is all about? Are you in need of reliable, low-maintenance, world-renowned vibrating motors? Drop us a question at https://www.uras-techno.co.jp/en/support/contact/ and we’ll get back to you asap!

March 14, 2024

Unlocking Efficient Vertical Motion

While most of our machines we showcase here provide linear motion like feeders, screens and so on, vibrating motors can also provide vertical motion as shown with the Vibro Lift. In most cases, vertical motion can only be provided by two vibrating motors set perpendicular to each other. However, we provide a more space efficient solution with the patented Uras Techno Gearbox.

The Gearbox syncs up two vibrators that are set parallel to each other, but are still capable of delivering vertical motion!

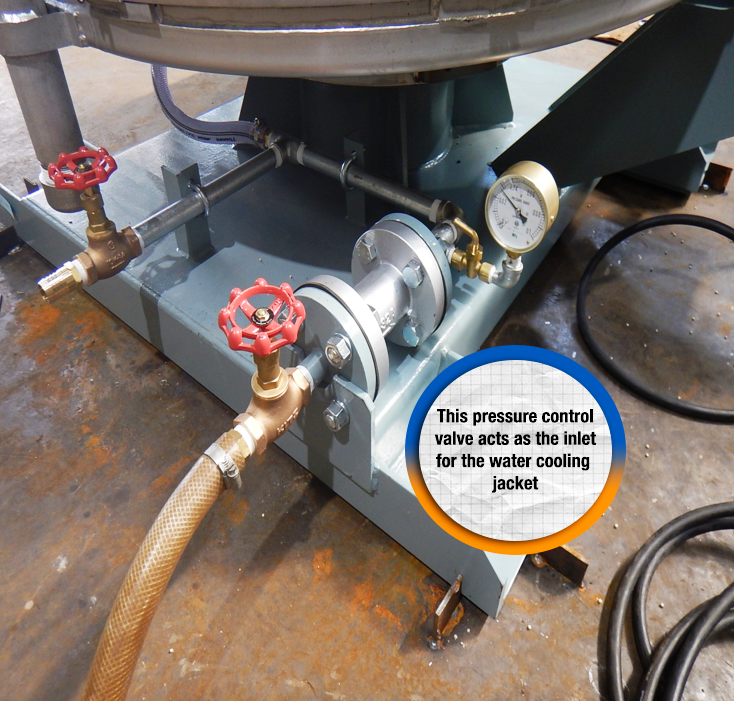

This particular Vibro Lift transported PVC pellets from one application to the next, and was equipped with a water jacket to cool the material before arrival at the next application.

💡Compact footprint on your factory floor

💡Cooling, heating, drying, or dusting, all during transportation

💡Powered by two 6 pole Uras Vibrators, the ultimate in Japanese-made vibrating motors

Tired of constantly replacing your motors? Switch to Uras and never look back! Learn more about us and our team at https://www.uras-techno.co.jp/en/products/uras_vibrator/, or leave a comment down below.

March 6, 2024

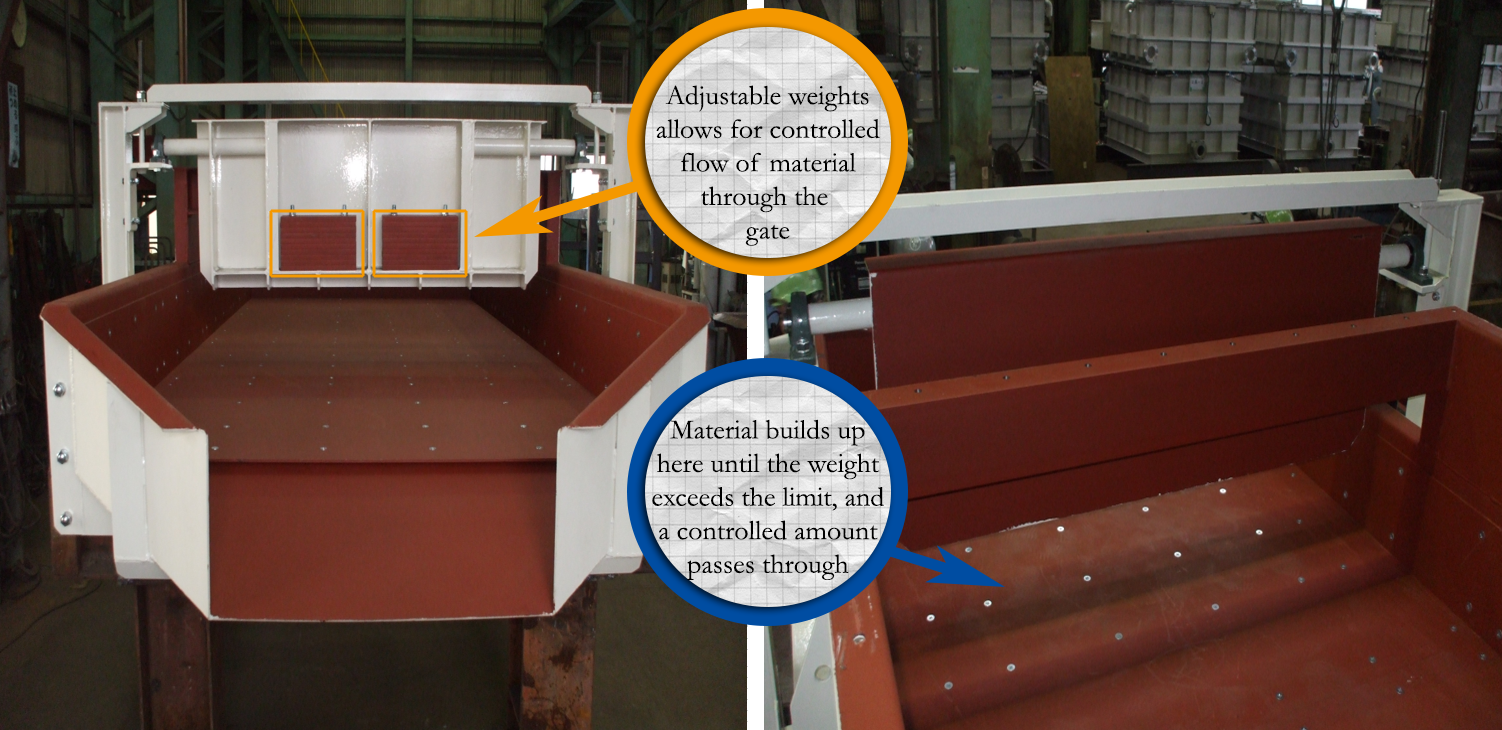

Adjustable Feeder for Bulk Solids

The name of the game with this feeder is adjustability! When adjusting material flow comes to mind for bulk solids, a hopper comes to mind. However our customer was feeding large, ceramic cylinders with approximate dimensions 3” x 5.5” x 8”, so a hopper that would generally work with bulk solids was not an option.

This feeder was constructed to allow them to control the flow of their ceramics with weights attached to free-moving gates attached to the frame. The material would build up behind the gate until the weight was large enough to open the gate, allowing a certain amount of material through before the gate would close again and the process would start again. The weights were adjustable, allowing them to freely control the flow of their product by simply adding or removing weights by hand.

As mentioned the gate was attached to the frame, so there was no chance of damage to the gate through the strong vibrations produced by the Uras Vibrator. The customer was happy with the initial testing data, and loved the reliability and low maintenance of the Uras Vibrator.

Let us know in the comments if you’re interested in more details about the feeder, vibrator, or engineering behind our products.