News Releases

December 18, 2023

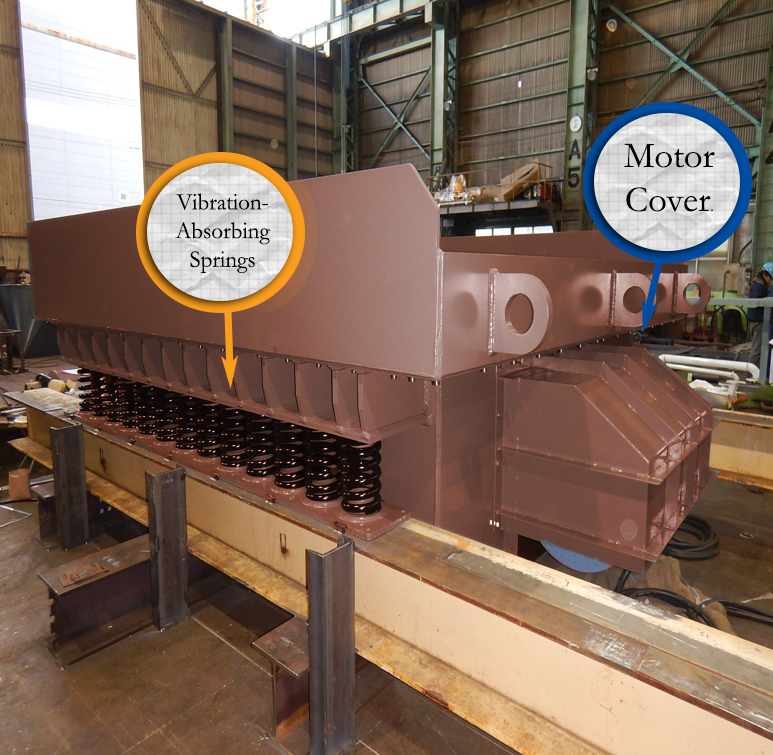

Unpacking Castings with a Vibro Shakeout

This beauty is called a Vibro Shakeout Machine. While some vibrating tables are used for packing, filling, removing air bubbles, etc., this one is used specifically for unpacking castings or shaking out molding boxes. It’s powered by two 8-pole vibrators that give it enough power to quickly and efficiently do its job. The compression springs isolate the vibration, so there is no damage done to the factory floor.

🎯 high efficiency leads to big time savings

🎯 low maintenance Uras Vibrators means less down time

🎯 motor covers protect vibrators from outside damage

December 11, 2023

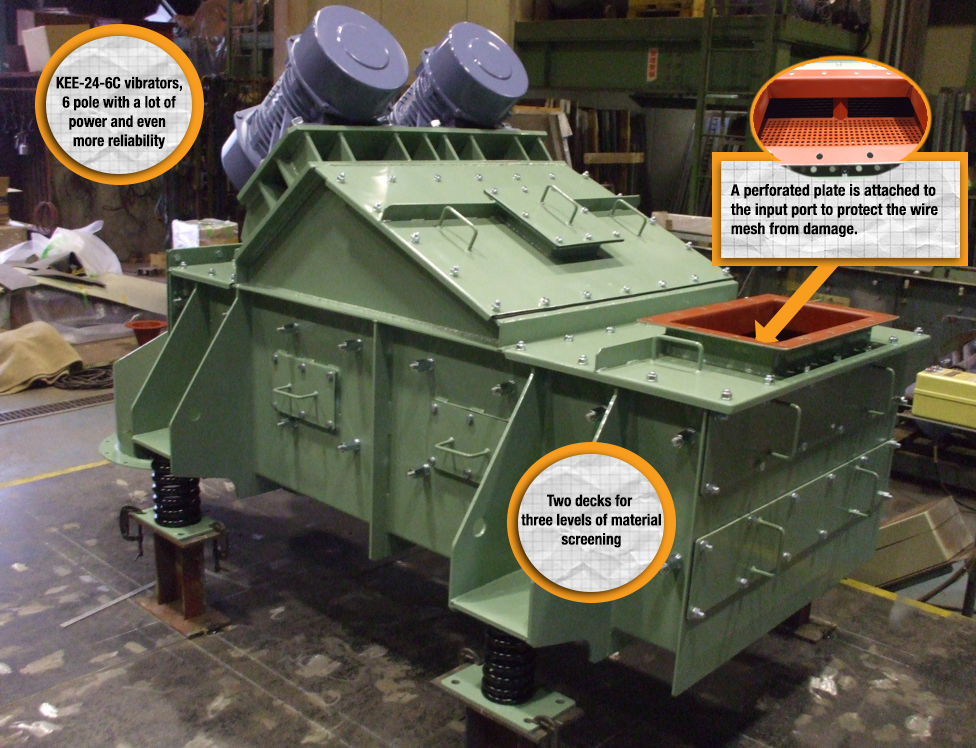

Powerful vibrations for the chemical industry

This vibrating screen went to one of our friends in the chemical industry to assist in the preparation of ferrovanadium by screening vanadium oxide. They needed a uniform mixture of grains that were approximately 9mm to 15mm in size, bigger or smaller went their separate ways to a different production. This double deck screen powered by Uras Techno Vibrators were exactly what they needed, with three levels of separation to get the exact size of powder necessary for their operation.

⚗️Perfect for the bulk handling needs in the chemical industry

⚗️Decks are easily removable for regular maintenance and cleaning

⚗️Powered by two 6 pole Uras Vibrators, constructed using strict Japanese standards for the ultimate in reliability

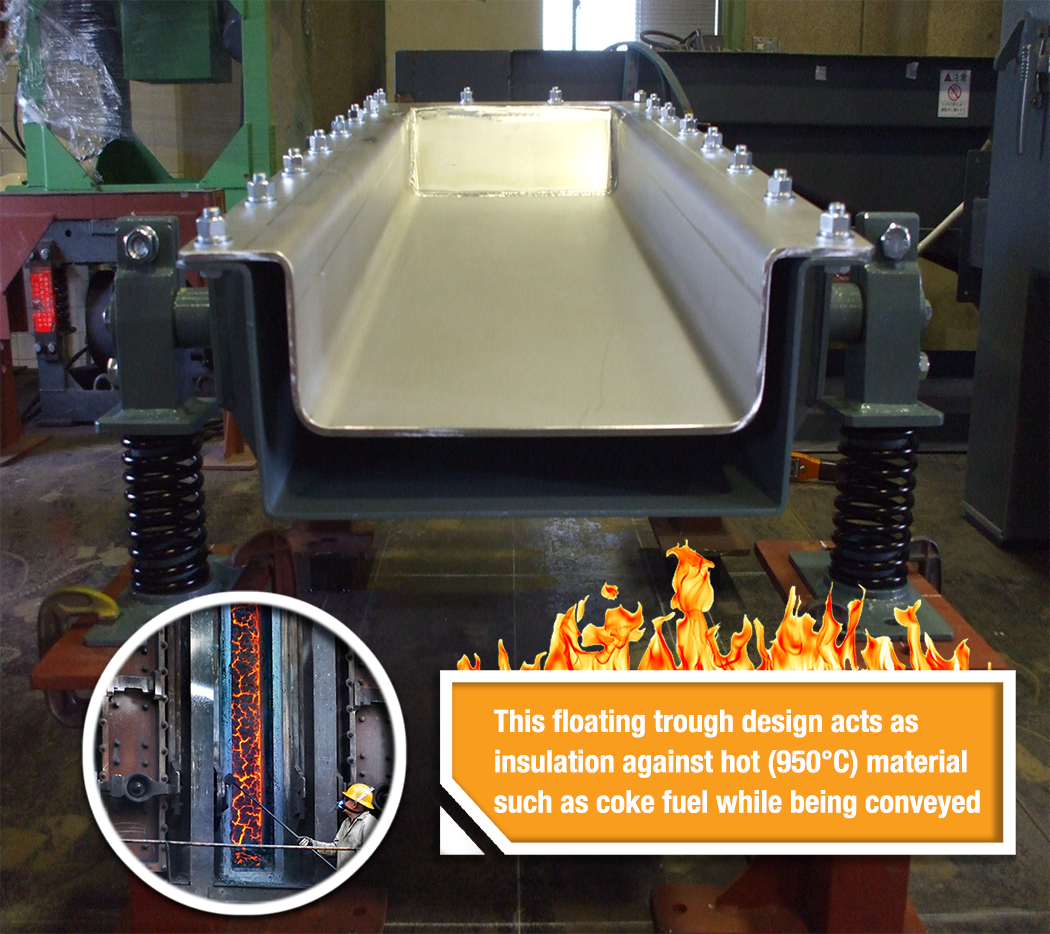

December 5, 2023

Conveying High Temperature Materials

One of the huge advantages to switching to #vibration is you can easily work with extremely hot materials without risk to the equipment. And when I say hot, I mean hot. No like, HOT 🔥

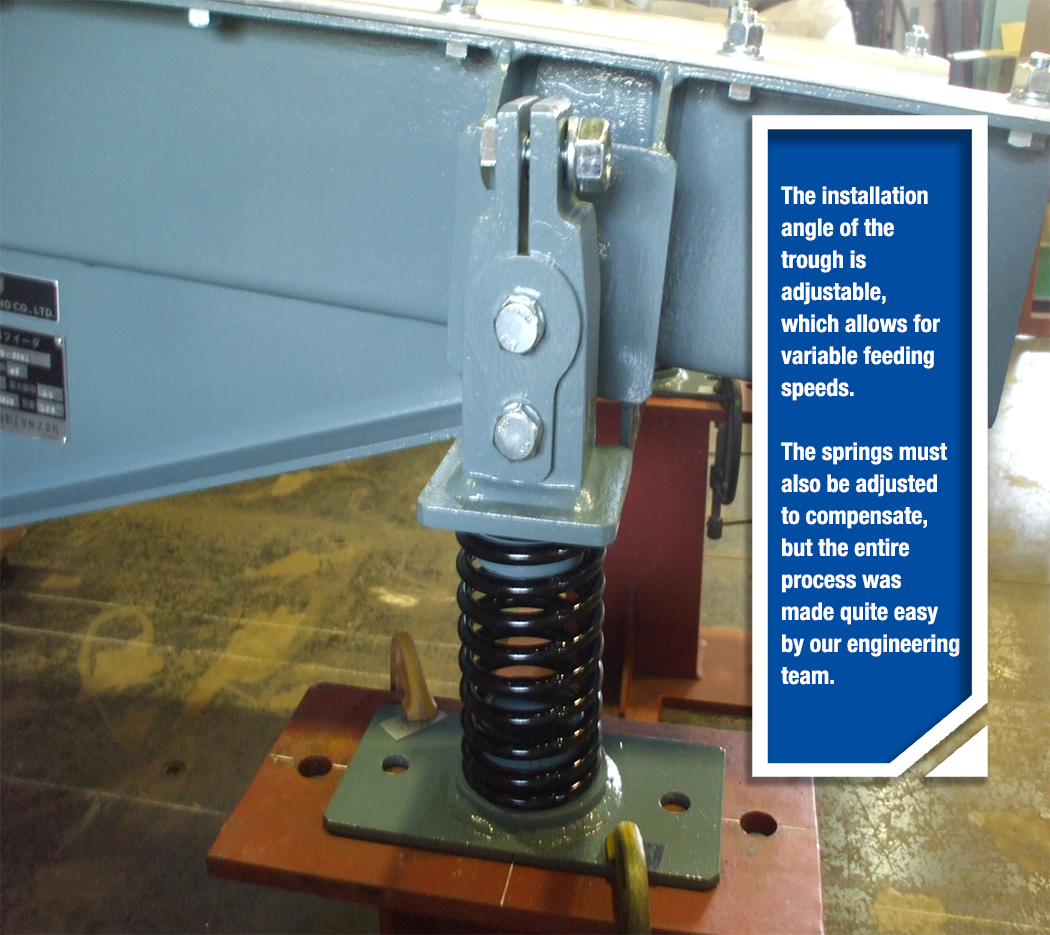

This feeder was made to easily deal with coke fuel at 950°C (~1700°F), a temperature which would easily melt even the most heat-resistant conveyor belt. This kind of temperature would also deal heavy damage to our vibrators if they were directly bolted to a surface that hot, so our engineers provided a floating trough made of stainless steel to provide the necessary insulation.

Not only that, but the bolts allow for adjustment of the trough. This in turn affects the installation angle of the vibrator, allowing for a significantly faster or slower feed to the next process.

Do you use vibration to work with high temperature materials? Let us know what kind of setup you’re using!

December 5, 2023

Uras Techno is coming to India!

Mark your calendars, because Uras Techno is heading to India!

Invest in reliability and durability → Invest in success

Stop wasting money on replacements → Use vibrating motors that LAST

Unleash your potential → Explore the future of efficiency

December 12th through 16th, we’ll set up shop in stall S500, Hall 4 at Excon, the largest construction equipment event in all of South Asia.

See ya there!