News Releases

September 3, 2021

Plasterboard Vibrating Screen

After rounds and rounds of testing, this vibrating screen made specifically for the recycling market made it out of our factory and into the hands of its new loving home.

It helped process a ratio of 9:1 gypsum to paper load, and help remove all powder before the material reached the next process.

♻️ soft vinyl cover for easy maintenance and confirmation of processed material

♻️ small “stairstep” on the trough helps to separate powder from the gypsum remains

♻️ all made possible by the smooth, linear vibration courtesy of dual 6 pole Uras Vibrators

July 26, 2021

Heat-Loss Prevention in a Conveyor

Vibro Conveyor made for conveying high-temperature material.

Are you working with a material that needs to stay hot through the entire transport process?

🔥 Insulation to prevent loss of heat during transportation process

🔥 Detachable trough to easily replace or repair damage

🔥 Powerful linear motion created by dual 8-pole Uras Vibrators

Many of our clients work with dangerously hot materials such as coke fuel that need to cool down in between processes due to either processing reasons or safety concerns. However, our recent client needed to keep ingots hot throughout transportation. The problem came when air entered through the conveyor and cooled down the ingots before moving into the furnace. Upon arrival, the temperature was too low to be used efficiently.

The fix was simple and inexpensive; glass wool insulation was installed underneath and along the vibrating conveyor. This kept the temperature of the ingots stable and protected the workers from the immense heat radiating from the trough.

Vibro Conveyor made for conveying high-temperature material!

Vibro Conveyor made for conveying high temperature material, used in mining, casting industries.

July 12, 2021

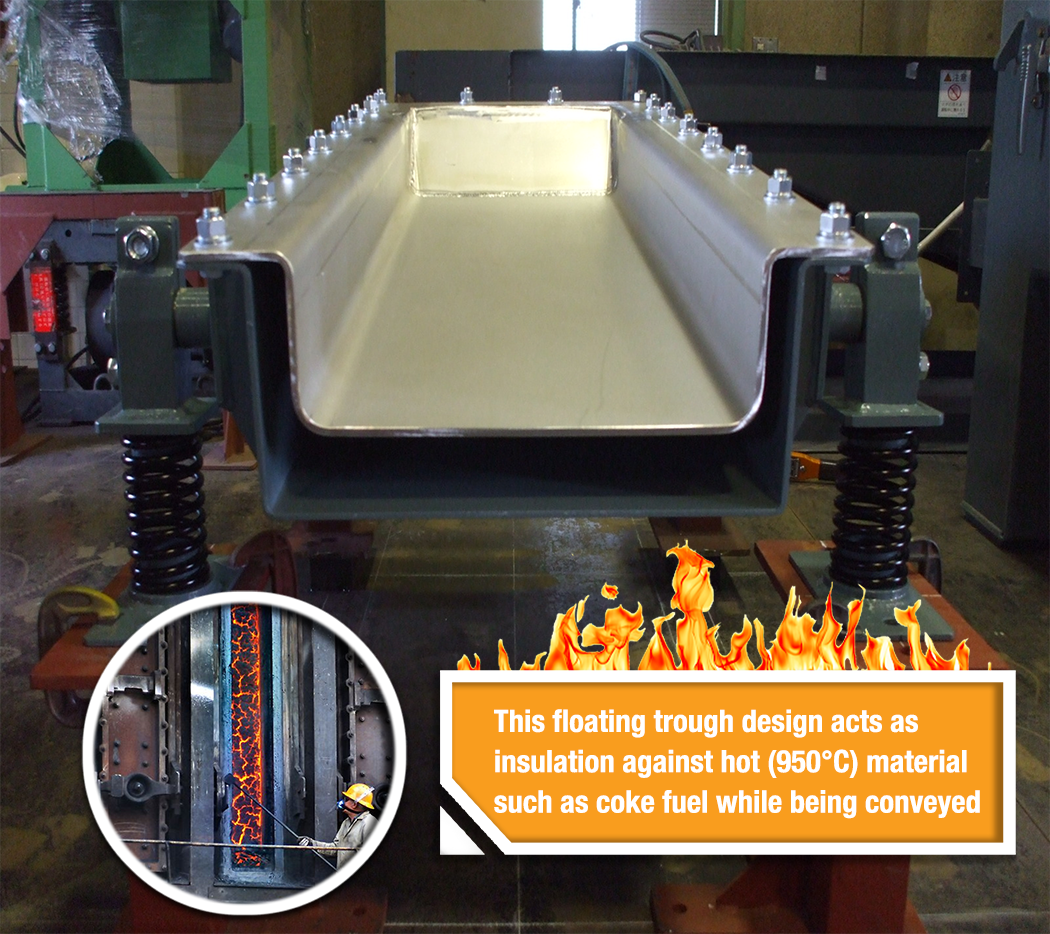

Working With High Temperature (950°C) Materials

Vibrating feeder made for conveying high temperature material, used in mining, casting industries.

One of the huge advantages to working with #vibration is you can easily work with extremely hot materials without risk to the equipment. And when we say hot, we mean hot. No like, HOT 🔥

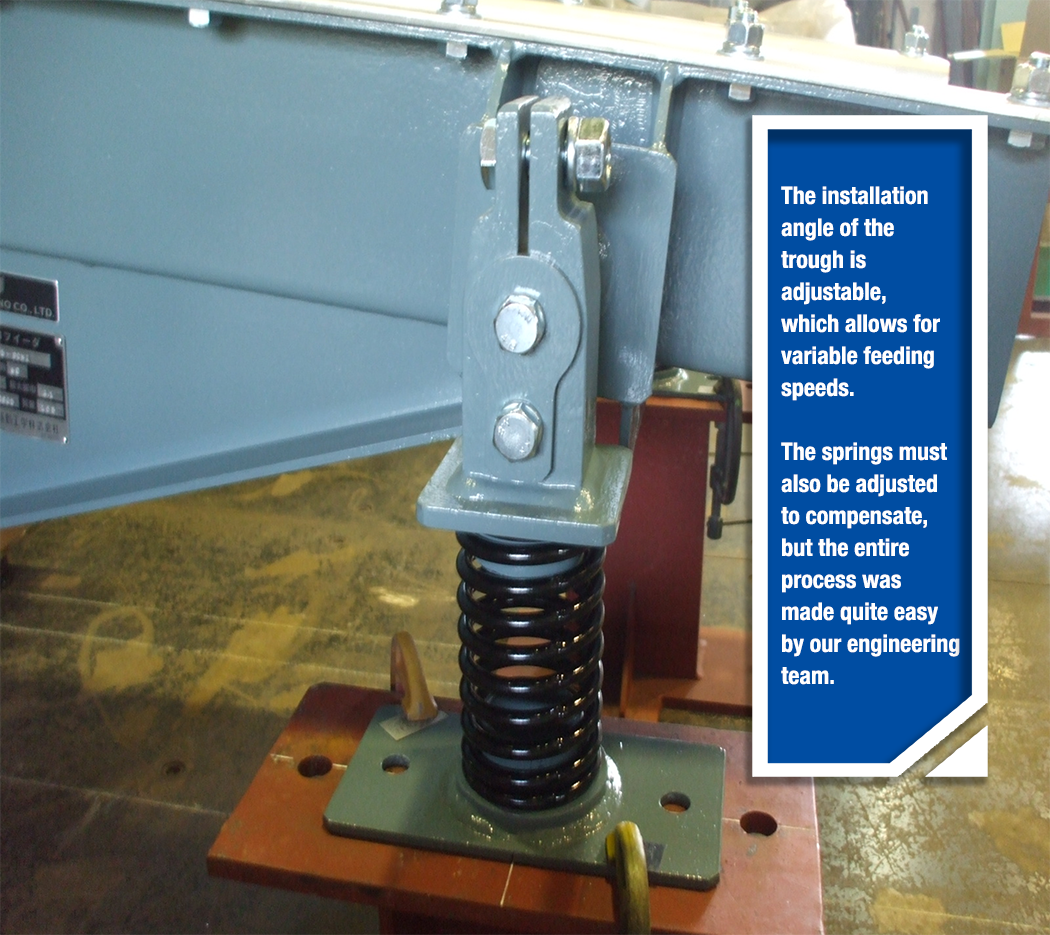

This feeder was made to easily deal with coke fuel at 950°C (~1700°F), a temperature which would easily melt even the most heat-resistant conveyor belt. This kind of temperature would also deal heavy damage to our vibrators if they were directly bolted to a surface that hot, so our engineers provided a floating trough made of stainless steel to provide the necessary insulation.

Not only that, but the bolts allow for adjustment of the trough. This in turn affects the installation angle of the vibrator, allowing for a significantly faster or slower feed to the next process.

May 26, 2021

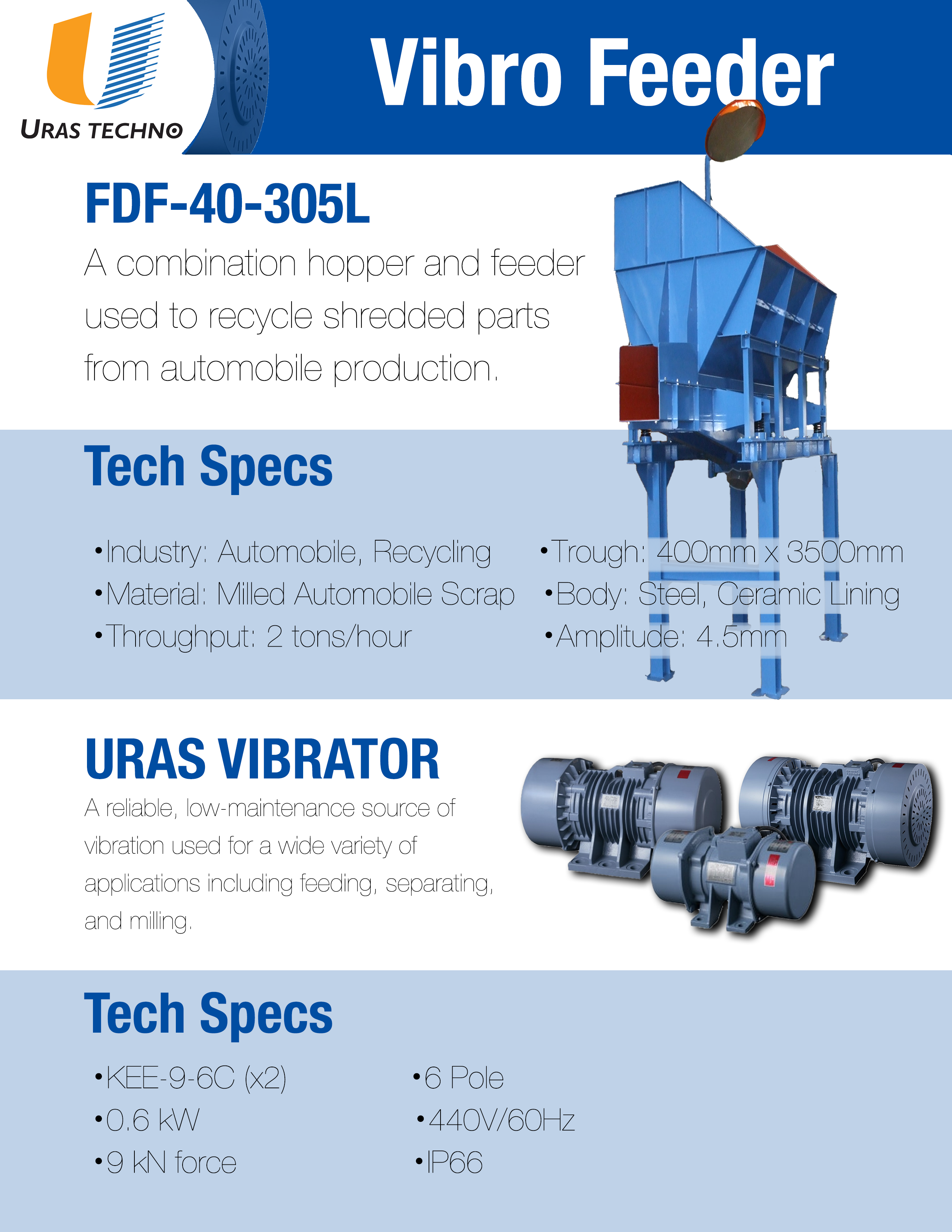

Combination Hopper & Feeder

This tall boy was used as part of a larger operation to sort and recycle shredded automobile parts. This particular application received material through the attached hopper, which allowed the vibrating feeder to send controlled amounts of material to the next process.

An interesting part of this setup is that while the hopper outputs directly to the feeder, it’s ultimately connected to the frame. This means it doesn’t receive vibrations from the dual six pole Uras Vibrators attached to the feeder itself. If the user was having trouble with rat holing or bridging in the hopper, they’d have to attach another vibrator directly to the side of the hopper; either a smaller Uras unit, or an air vibrator from our good friends at @The Cleveland Vibrator Company.

♻ Combination Hopper and Vibro Feeder for max efficiency in one unit.

♻ Attached mirror to easily view state of material going through hopper

♻ Ceramic lining for added hopper protection

The Vibro Feeder is powered by two KEE-9-6CW Uras Vibrators, while the hopper is powered by love ❤️ (and gravity).