News Releases

May 2, 2025

Feeding Fine Gypsum Powder with Maximum Efficiency

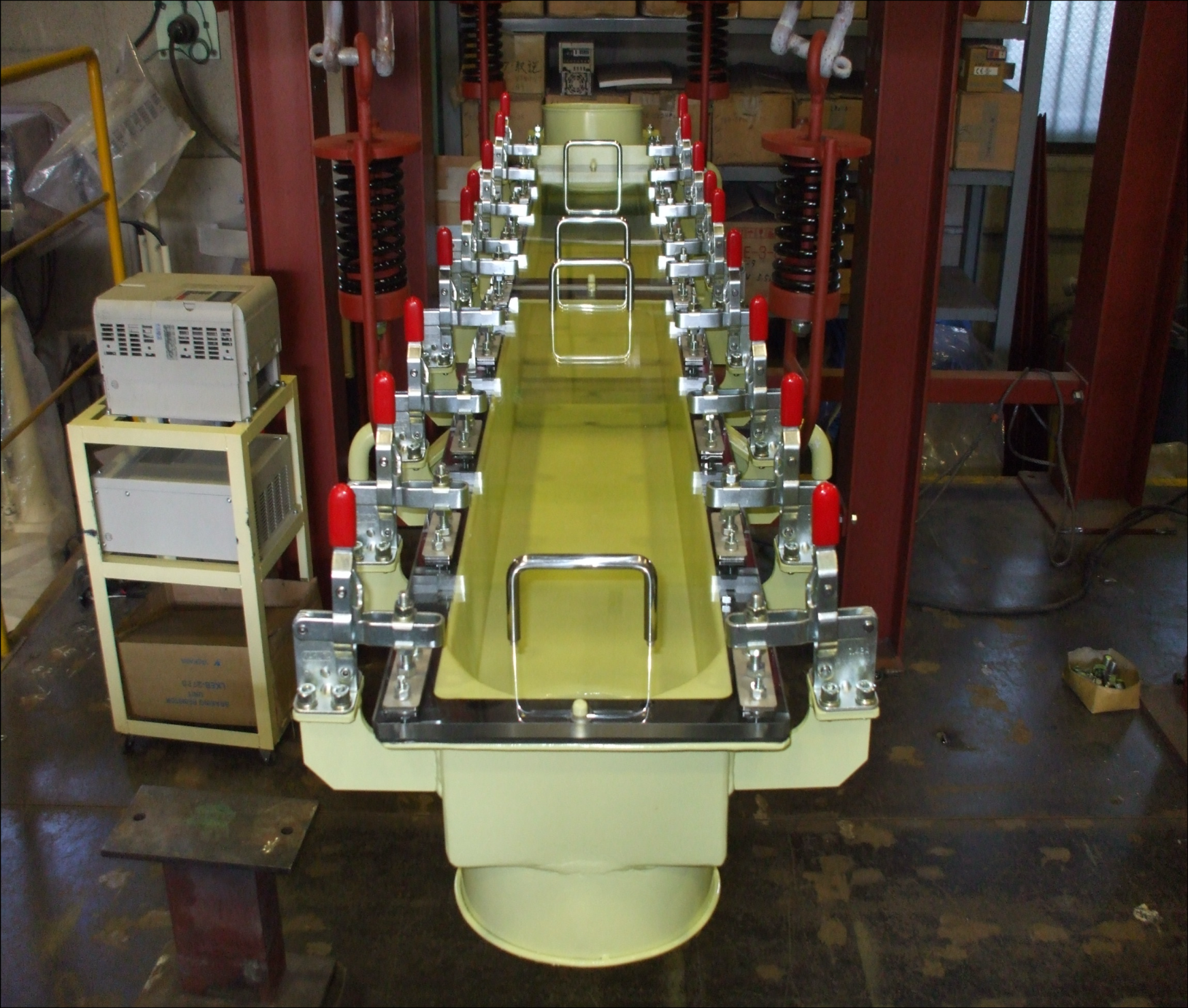

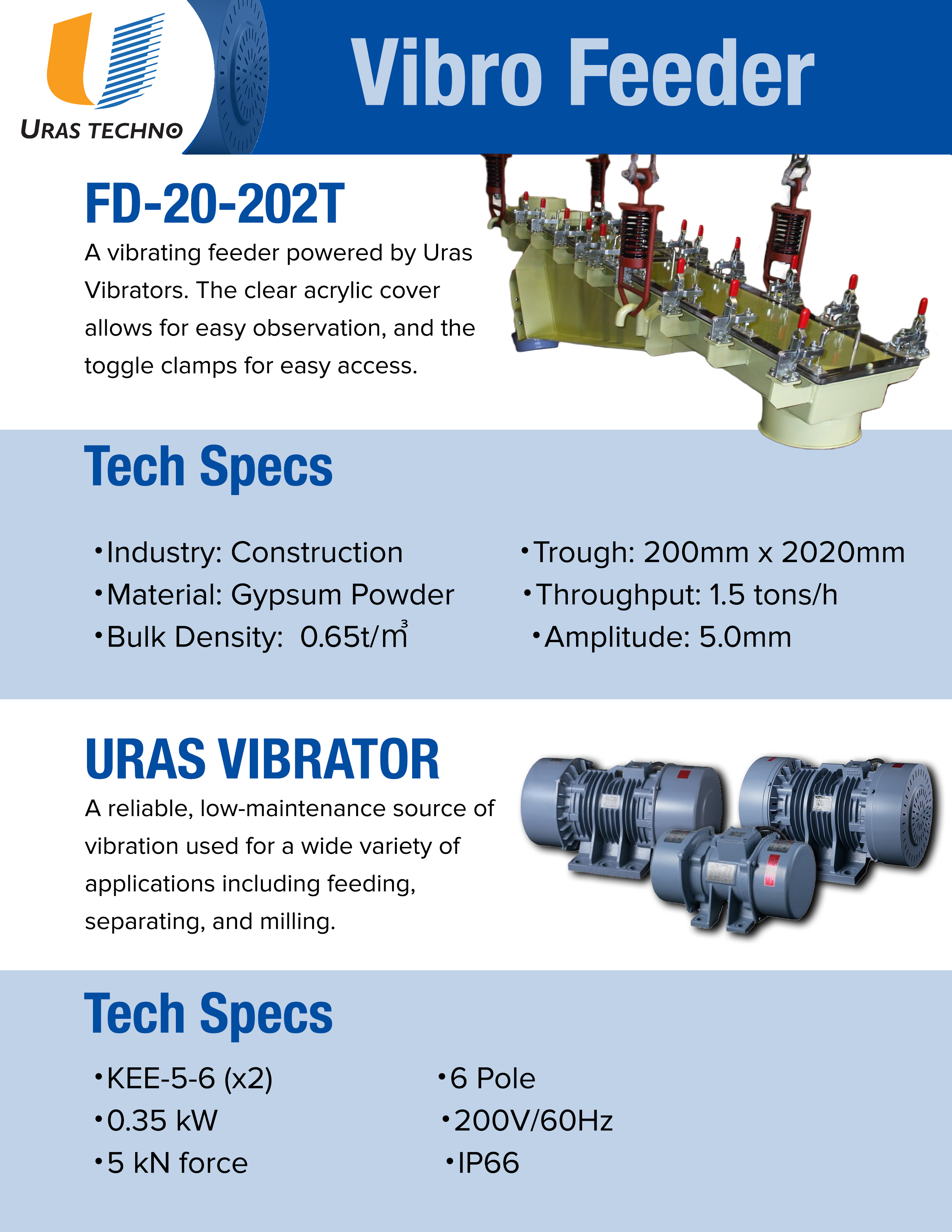

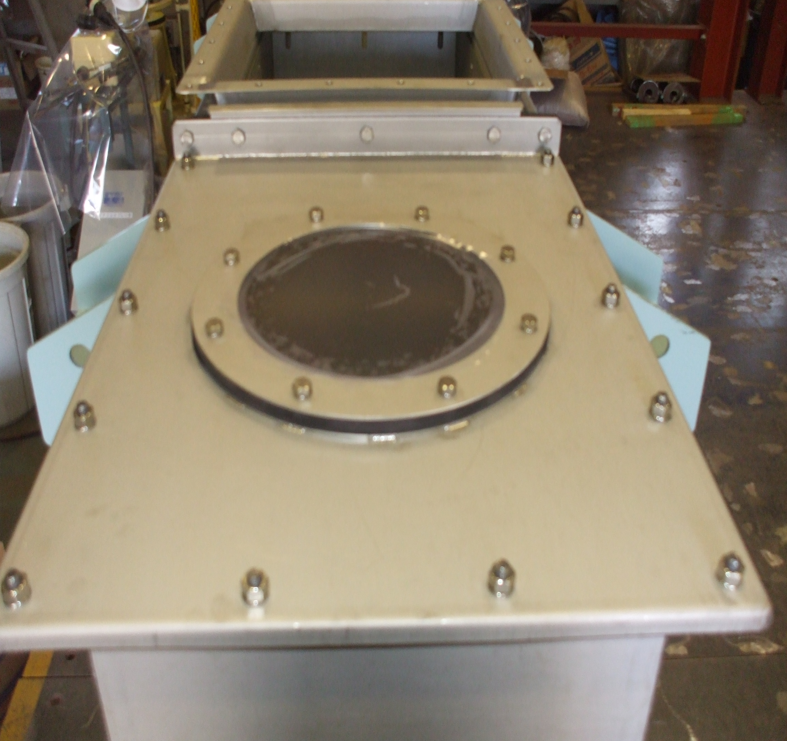

This feeder was built for a construction materials supplier with two goals in mind:

1️⃣ Reliably feed gypsum powder from a circular sieve

2️⃣ Look good doing it

The clear acrylic cover, designed at the client’s request, offers full visibility of the material flow and easy access for quick maintenance. It’s sleek, functional, and efficient.

The dual Uras Vibrators ensure steady, dependable operation, offering the reliability that sets us apart in the industry.

March 21, 2025

Versatile. Reliable. Built to Perform.

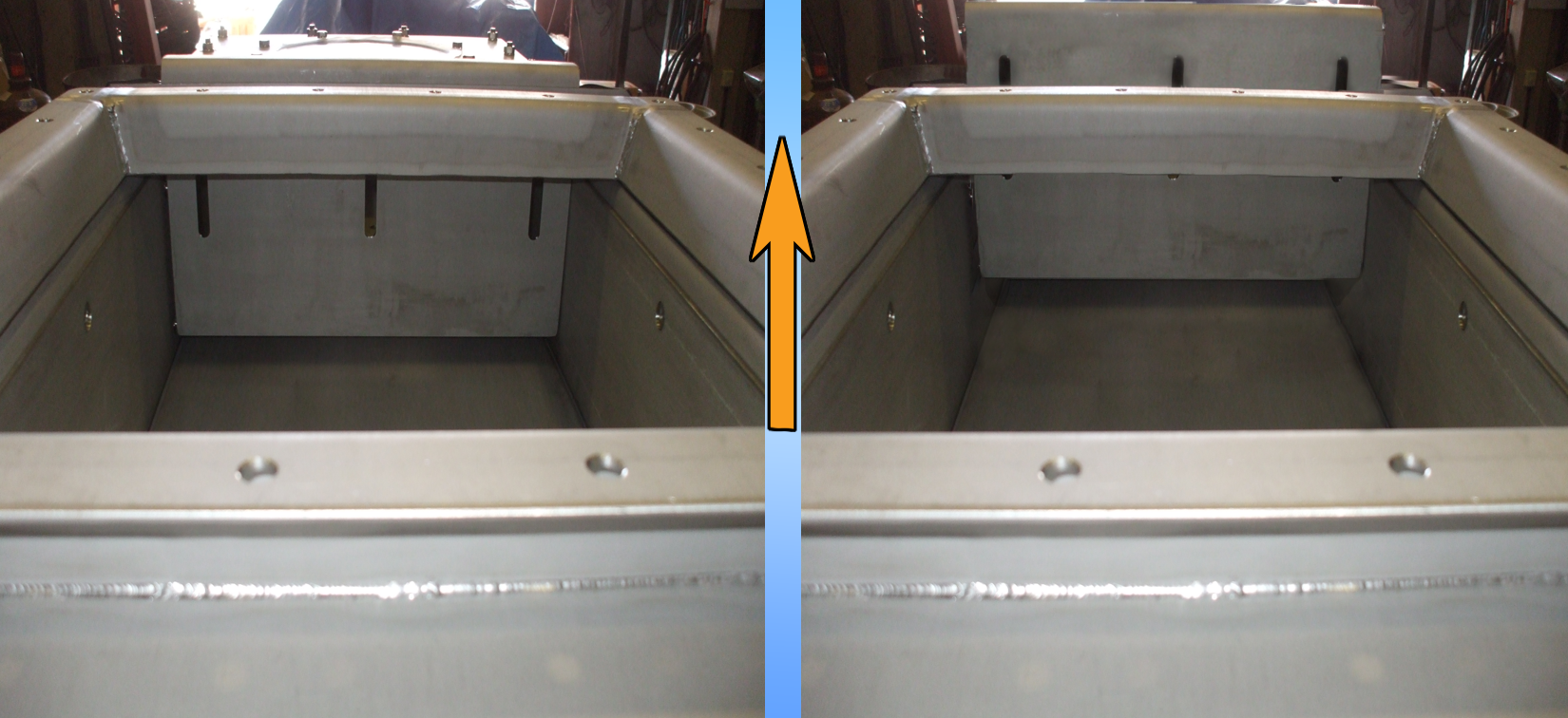

A food manufacturing company came to us with a challenge:

・ One machine to feed multiple types of food products (mainly noodles)

・ Ability to feed two different products at the same time

・ Adjustable material throughput

Our solution? This custom-built feeder:

・ Adjustable center gate – Locked in place with three bolts for easy cleaning & quick adjustments

・ Hygienic stainless steel body – Simple spray-down for fast changeovers

・ Powered by two KEE-3-6 Uras Vibrators – 0.2kW, 6-pole, 220V, 60Hz for low-maintenance reliability

After shipment, the customer told us they were extremely pleased with the results!

February 27, 2025

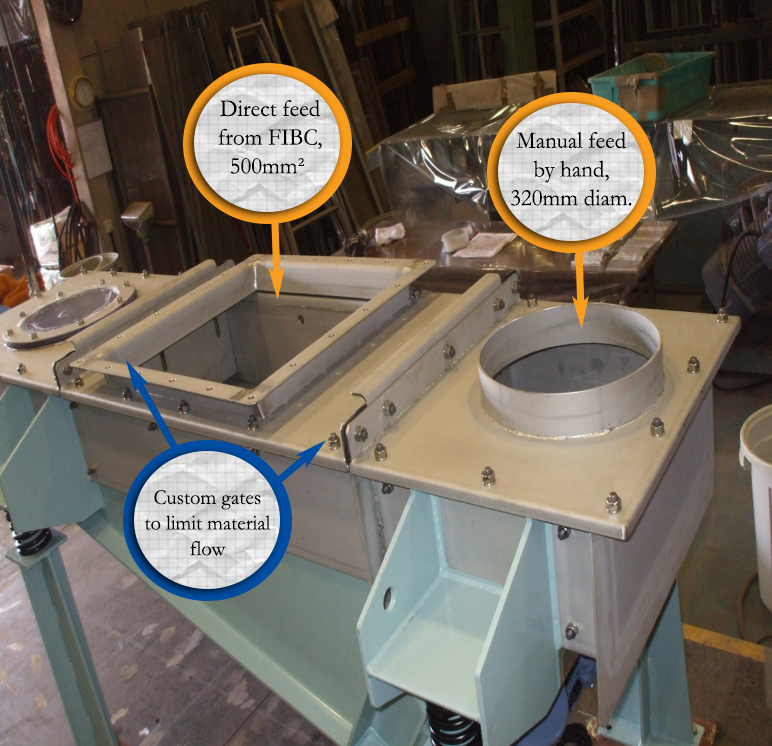

Smarter Carbon Feeding Solutions

Our client needed variable levels of carbon feeding, with access to two different inputs. The main input was used for direct feeding from large flexible containers, while the smaller port was used for manual input. The client occasionally needed to feed in separate raw materials by hand from the floor.

Each input came with its own adjustable gate to limit material flow from anywhere between 30mm to 150mm from the bottom of the surface lining. This allowed them to control the amount of carbon that went on to the next process, to stabilize the material layer thickness and prevent clogging.

Along with this, we installed clear polycarbonate windows near the discharge chute that that allowed them to monitor their product output.

Overall our client was happy with the two gate, two input additions, a simple setup which allowed for a lot of customization on their end.

And of course the stars of the show, two 4-pole KEE-9-4C Uras Motors that added reliability and low-maintenance to the mix.

February 13, 2025

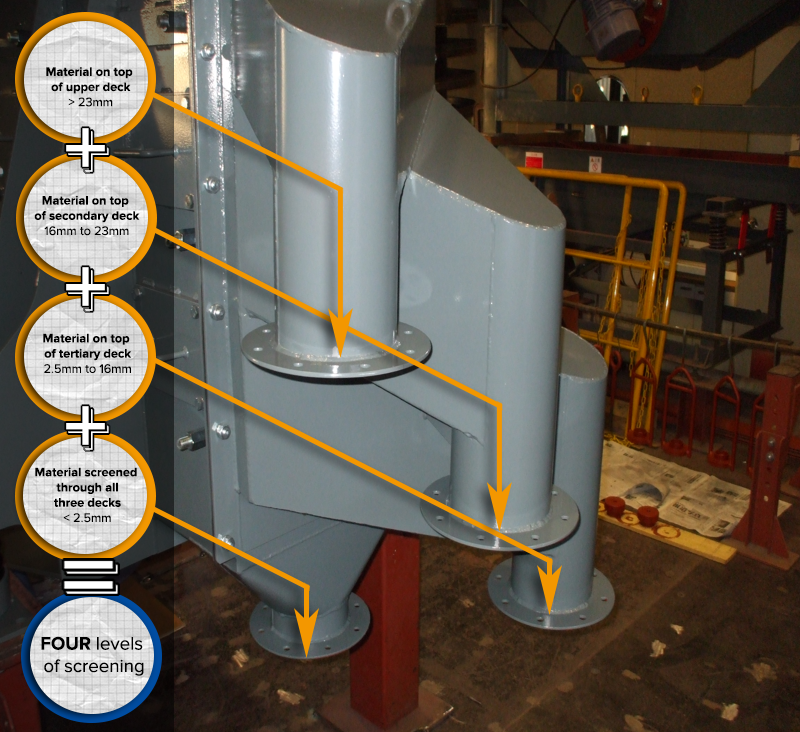

Multiple levels of separation with simple vibration

This monster of a screen was requested by a company who needed a lot of semi-fine separating for metals used in the manufacturing of rechargeable batteries. The majority of the material started out at 30mm or larger. They required it to be screened with 23mm aperture (flat top screen), 13mm (flat top screen), and 2.5mm (normal weave incl. tapping balls).

Also, we installed inspection ports for every possible stage of the process, so they could be sure everything was running smoothly.

With a trough size of 450mm by 1800mm and 5 tons per hour throughput, our client was extremely satisfied.

The whole operation is powered by two KEE-24-6C 6-pole Uras Vibrators.